Verbindungstechnik

Elektronik

Automatisierung & Software

Werkstatt & Zubehör

Assemblierung

Reihenklemmen

Steckverbinder

Leiterplattenklemmen und –steckverbinder

Gehäusesysteme und Komponenten

Kontaktlose Verbindungstechnik

Kabeleinführungssysteme und Komponenten

Leitungssätze, Patchkabel und Kabel

SPS-Schnittstellen und Migrationslösungen

Serviceschnittstellen

Verteilerboxen

OMNIMATE 4.0

Leiterplatten-Steckverbinder - OMNIMATE Data

Leiterplatten-Klemmen - OMNIMATE Signal

Leiterplatten-Steckverbinder - OMNIMATE Signal

Leiterplatten-Klemmen - OMNIMATE Power

Leiterplattensteckverbinder - OMNIMATE Power

Durchführungsklemmen für Geräte - OMNIMATE Power

Leiterplatten-Rundsteckverbinder – IP67

Muster Set - OMNIMATE

Single-Pair-Ethernet

Ethernet-Leiterplattenklemme

Ethernet-APL

RJ45-Buchse modular

RJ45-Übertrager-Buchse

USB-Buchse

LM APL 5.08/03/135 3.5SN OR BX

Allgemeine Bestelldaten

Ausfuehrung

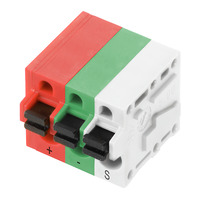

Leiterplattenklemme, 5.08 mm, Polzahl: 3, 135°, Lötstiftlänge (l): 3.5 mm, verzinnt, orange, Zugbügelanschluss, Klemmbereich, max. : 2.5 mm², Box

Best.-Nr.

2873490000

Art

LM APL 5.08/03/135 3.5SN OR BX

GTIN (EAN)

4064675644521

VPE

500 Stück

Produkt-Kennzahlen

IEC: 630 V / 17.5 A / 0.2 - 2.5 mm²

Verpackung

Box

Abmessungen und Gewichte

Tiefe

13,9 mm

Tiefe (inch)

0,547 inch

Höhe

19 mm

Höhe (inch)

0,748 inch

Höhe niedrigstbauend

15,5 mm

Breite

15,79 mm

Breite (inch)

0,622 inch

Nettogewicht

3,804 g

Umweltanforderungen

REACH SVHC

/

RoHS-Konformitätsstatus

Konform ohne Ausnahme

Elektrische Eigenschaften

Durchgangswiderstand

1,20 mΩ

Systemkennwerte

Anzahl Lötstifte pro Pol

1

Bestückungsloch-Durchmesser (D)

1,3 mm

Bestückungsloch-Durchmesser Toleranz (D)

+ 0,1 mm

Lötstift-Abmessungen

0,95 x 0,8 mm

Lötstiftlänge (l)

3,5 mm

Lötstiftposition-Toleranz

± 0,1 mm

Lötverfahren

Handlöten, Wellenlöten

Montage auf der Leiterplatte

THT-Lötanschluss

Polzahl

3

Produktfamilie

OMNIMATE Signal - Serie LM

Raster in Zoll (P)

0,2 "

Raster in mm (P)

5,08 mm

Schutzart

IP20

Seitenabschluss, Eigenschaft

seitlich geschlossen

Werkstoffdaten

Isolierstoff

Wemid (PA)

Farbe

orange

Farbtabelle (ähnlich)

RAL 2000

Isolierstoffgruppe

I

Kriechstromfestigkeit (CTI)

≥ 600

Brennbarkeitsklasse nach UL 94

V-0

Kontaktmaterial

Cu-leg

Kontaktoberfläche

verzinnt

Beschichtung

1-3 μm Ni, 4-6 μm SN

Verzinnungsart

matt

Schichtaufbau - Lötanschluss

1...3 µm Ni / 4...6 µm Sn matt

Lagertemperatur, min.

-40 °C

Lagertemperatur, max.

70 °C

Betriebstemperatur, min.

-50 °C

Betriebstemperatur, max.

120 °C

Verpackungen

Verpackung

Box

VPE Länge

491 mm

VPE Breite

341 mm

VPE Höhe

164 mm

Typprüfungen

Prüfung: Haltbarkeit der Markierungen

Prüfung

Ursprungskennzeichnung, Typkennzeichnung, Raster, Materialtyp, Zulassungskennzeichnung UL, Zulassungskennzeichnung CSA, Lebensdauer

Bewertung

vorhanden

Prüfung: Klemmbarer Querschnitt

Norm

DIN EN 60999-1 Abschnitt 7 und 9.1 / 12.00, DIN EN 60947-1 Abschnitt 8.2.4.5.1 / 12.02

Leitertyp

Leitertyp und Leiterquerschnitt

eindrähtig 0,2 mm²

Leitertyp und Leiterquerschnitt

mehrdrähtig 0,2 mm²

Leitertyp und Leiterquerschnitt

mehrdrähtig 1,5 mm²

Leitertyp und Leiterquerschnitt

eindrähtig 2,5 mm²

Leitertyp und Leiterquerschnitt

AWG 24/1

Leitertyp und Leiterquerschnitt

AWG 24/19

Leitertyp und Leiterquerschnitt

AWG 14/1

Leitertyp und Leiterquerschnitt

AWG 14/19

Bewertung

bestanden

Prüfung auf Beschädigung und unbeabsichtigtes Lösen von Leitern

Norm

DIN EN 60999-1 Abschnitt 9.4 / 12.00

Anforderung

0,2 kg

Leitertyp

Leitertyp und Leiterquerschnitt

mehrdrähtig 0,25 mm²

Leitertyp und Leiterquerschnitt

AWG 24/1

Leitertyp und Leiterquerschnitt

AWG 24/19

Bewertung

bestanden

Anforderung

0,3 kg

Leitertyp

Leitertyp und Leiterquerschnitt

eindrähtig 0,5 mm²

Bewertung

bestanden

Anforderung

0,4 kg

Leitertyp

Leitertyp und Leiterquerschnitt

mehrdrähtig 1,5 mm²

Bewertung

bestanden

Anforderung

0,7 kg

Leitertyp

Leitertyp und Leiterquerschnitt

eindrähtig 2,5 mm²

Leitertyp und Leiterquerschnitt

AWG 14/1

Leitertyp und Leiterquerschnitt

AWG 14/19

Bewertung

bestanden

Pull-Out Test

Norm

DIN EN 60999-1 Abschnitt 9.5 / 12.00

Anforderung

≥10 N

Leitertyp

Leitertyp und Leiterquerschnitt

mehrdrähtig 0,25 mm²

Leitertyp und Leiterquerschnitt

AWG 24/1

Leitertyp und Leiterquerschnitt

AWG 24/19

Bewertung

bestanden

Anforderung

≥20 N

Leitertyp

Leitertyp und Leiterquerschnitt

H05V-U0.5

Bewertung

bestanden

Anforderung

≥40 N

Leitertyp

Leitertyp und Leiterquerschnitt

H07V-K1.5

Bewertung

bestanden

Anforderung

≥50 N

Leitertyp

Leitertyp und Leiterquerschnitt

H07V-U2.5

Leitertyp und Leiterquerschnitt

AWG 14/1

Leitertyp und Leiterquerschnitt

AWG 14/19

Bewertung

bestanden

Wichtiger Hinweis

IPC-Konformität

Konformität: Die Produkte werden nach international anerkannten Standards und Normen entwickelt, gefertigt und ausgeliefert und entsprechen den zugesicherten Eigenschaften im Datenblatt bzw. erfüllen dekorative Eigenschaften in Anlehnung der IPC-A-610 „Class2“. Darüber hinaus gehende Ansprüche an die Produkte können auf Anfrage bewertet werden.

Hinweise

Langzeitlagerung des Produkts bei einer Durchschnittstemperatur von 50 °C und einer maximalen Luftfeuchtigkeit von 70 %, 36 Monate

Klassifikationen

ETIM 6.0

EC002643

ETIM 7.0

EC002643

ETIM 8.0

EC002643

ETIM 9.0

EC002643

ECLASS 9.0

27-44-04-01

ECLASS 9.1

27-44-04-01

ECLASS 10.0

27-44-04-01

ECLASS 11.0

27-46-01-01

ECLASS 12.0

27-46-01-01

ECLASS 13.0

27-46-01-01

Zulassungen

Zulassungen

ROHS

Konform

UL File Number Search

UL Webseite

Zertifikat-Nr. (cURus)

E60693

Alle anzeigen

farbig

orange

schwarz

silbergrau

Farbe:

schwarz

Best.-Nr.:

8000094097

Art:

MPS APL 5/03 S F2 TN B B D D

Ausfuehrung:

Leiterplattensteckverbinder, Buchsenstecker, Raster in mm (P): 5.00 mm, Polzahl: 3, 180°, Box

Farbe:

orange

Best.-Nr.:

2872550000

Art:

BLZP APL 5.00HC/03/180F SN OR BX

Ausfuehrung:

Leiterplattensteckverbinder, Buchsenstecker, 5.00 mm, Polzahl: 3, 180°, Zugbügelanschluss, Klemmbereich, max. : 4 mm², Box

Farbe:

farbig

Best.-Nr.:

2873480000

Art:

LMF APL 5.00/03/90 3.5SN BX

Ausfuehrung:

Leiterplattenklemme, 5.00 mm, Polzahl: 3, 90°, Lötstiftlänge (l): 3.5 mm, verzinnt, orange, farbig, PUSH IN mit Betätigungselement, Klemmbereich, max. : 2.5 mm², Box

Farbe:

farbig

Best.-Nr.:

2873470000

Art:

LMF APL 5.00/03/180 3.5SN BX

Ausfuehrung:

Leiterplattenklemme, 5.00 mm, Polzahl: 3, 180°, Lötstiftlänge (l): 3.5 mm, verzinnt, orange, farbig, PUSH IN mit Betätigungselement, Klemmbereich, max. : 2.5 mm², Box

Farbe:

orange

Best.-Nr.:

2873500000

Art:

LM APL 5.08/03/90 3.5SN OR BX

Ausfuehrung:

Leiterplattenklemme, 5.08 mm, Polzahl: 3, 90°, Lötstiftlänge (l): 3.5 mm, verzinnt, orange, Zugbügelanschluss, Klemmbereich, max. : 2.5 mm², Box

Farbe:

silbergrau

Best.-Nr.:

2903230000

Art:

SH ETH U

Ausfuehrung:

Schirmbügel, Zubehör, Schraubflansch, Polzahl: 1, verzinkt, silbergrau, Box

Ausfuehrung

Leiterplattenklemme, 5.08 mm, Polzahl: 3, 135°, Lötstiftlänge (l): 3.5 mm, verzinnt, orange, Zugbügelanschluss, Klemmbereich, max. : 2.5 mm², Box

Best.-Nr.

2873490000

Art

LM APL 5.08/03/135 3.5SN OR BX

GTIN (EAN)

4064675644521

VPE

500 Stück

Produkt-Kennzahlen

IEC: 630 V / 17.5 A / 0.2 - 2.5 mm²

Verpackung

Box

Tiefe

13,9 mm

Tiefe (inch)

0,547 inch

Höhe

19 mm

Höhe (inch)

0,748 inch

Höhe niedrigstbauend

15,5 mm

Breite

15,79 mm

Breite (inch)

0,622 inch

Nettogewicht

3,804 g

REACH SVHC

/

RoHS-Konformitätsstatus

Konform ohne Ausnahme

Durchgangswiderstand

1,20 mΩ

Anzahl Lötstifte pro Pol

1

Bestückungsloch-Durchmesser (D)

1,3 mm

Bestückungsloch-Durchmesser Toleranz (D)

+ 0,1 mm

Lötstift-Abmessungen

0,95 x 0,8 mm

Lötstiftlänge (l)

3,5 mm

Lötstiftposition-Toleranz

± 0,1 mm

Lötverfahren

Handlöten, Wellenlöten

Montage auf der Leiterplatte

THT-Lötanschluss

Polzahl

3

Produktfamilie

OMNIMATE Signal - Serie LM

Raster in Zoll (P)

0,2 "

Raster in mm (P)

5,08 mm

Schutzart

IP20

Seitenabschluss, Eigenschaft

seitlich geschlossen

Isolierstoff

Wemid (PA)

Farbe

orange

Farbtabelle (ähnlich)

RAL 2000

Isolierstoffgruppe

I

Kriechstromfestigkeit (CTI)

≥ 600

Brennbarkeitsklasse nach UL 94

V-0

Kontaktmaterial

Cu-leg

Kontaktoberfläche

verzinnt

Beschichtung

1-3 μm Ni, 4-6 μm SN

Verzinnungsart

matt

Schichtaufbau - Lötanschluss

1...3 µm Ni / 4...6 µm Sn matt

Lagertemperatur, min.

-40 °C

Lagertemperatur, max.

70 °C

Betriebstemperatur, min.

-50 °C

Betriebstemperatur, max.

120 °C

Verpackung

Box

VPE Länge

491 mm

VPE Breite

341 mm

VPE Höhe

164 mm

Prüfung: Haltbarkeit der Markierungen

Prüfung

Ursprungskennzeichnung, Typkennzeichnung, Raster, Materialtyp, Zulassungskennzeichnung UL, Zulassungskennzeichnung CSA, Lebensdauer

Bewertung

vorhanden

Prüfung: Klemmbarer Querschnitt

Norm

DIN EN 60999-1 Abschnitt 7 und 9.1 / 12.00, DIN EN 60947-1 Abschnitt 8.2.4.5.1 / 12.02

Leitertyp

Leitertyp und Leiterquerschnitt

eindrähtig 0,2 mm²

Leitertyp und Leiterquerschnitt

mehrdrähtig 0,2 mm²

Leitertyp und Leiterquerschnitt

mehrdrähtig 1,5 mm²

Leitertyp und Leiterquerschnitt

eindrähtig 2,5 mm²

Leitertyp und Leiterquerschnitt

AWG 24/1

Leitertyp und Leiterquerschnitt

AWG 24/19

Leitertyp und Leiterquerschnitt

AWG 14/1

Leitertyp und Leiterquerschnitt

AWG 14/19

Bewertung

bestanden

Prüfung auf Beschädigung und unbeabsichtigtes Lösen von Leitern

Norm

DIN EN 60999-1 Abschnitt 9.4 / 12.00

Anforderung

0,2 kg

Leitertyp

Leitertyp und Leiterquerschnitt

mehrdrähtig 0,25 mm²

Leitertyp und Leiterquerschnitt

AWG 24/1

Leitertyp und Leiterquerschnitt

AWG 24/19

Bewertung

bestanden

Anforderung

0,3 kg

Leitertyp

Leitertyp und Leiterquerschnitt

eindrähtig 0,5 mm²

Bewertung

bestanden

Anforderung

0,4 kg

Leitertyp

Leitertyp und Leiterquerschnitt

mehrdrähtig 1,5 mm²

Bewertung

bestanden

Anforderung

0,7 kg

Leitertyp

Leitertyp und Leiterquerschnitt

eindrähtig 2,5 mm²

Leitertyp und Leiterquerschnitt

AWG 14/1

Leitertyp und Leiterquerschnitt

AWG 14/19

Bewertung

bestanden

Pull-Out Test

Norm

DIN EN 60999-1 Abschnitt 9.5 / 12.00

Anforderung

≥10 N

Leitertyp

Leitertyp und Leiterquerschnitt

mehrdrähtig 0,25 mm²

Leitertyp und Leiterquerschnitt

AWG 24/1

Leitertyp und Leiterquerschnitt

AWG 24/19

Bewertung

bestanden

Anforderung

≥20 N

Leitertyp

Leitertyp und Leiterquerschnitt

H05V-U0.5

Bewertung

bestanden

Anforderung

≥40 N

Leitertyp

Leitertyp und Leiterquerschnitt

H07V-K1.5

Bewertung

bestanden

Anforderung

≥50 N

Leitertyp

Leitertyp und Leiterquerschnitt

H07V-U2.5

Leitertyp und Leiterquerschnitt

AWG 14/1

Leitertyp und Leiterquerschnitt

AWG 14/19

Bewertung

bestanden

IPC-Konformität

Konformität: Die Produkte werden nach international anerkannten Standards und Normen entwickelt, gefertigt und ausgeliefert und entsprechen den zugesicherten Eigenschaften im Datenblatt bzw. erfüllen dekorative Eigenschaften in Anlehnung der IPC-A-610 „Class2“. Darüber hinaus gehende Ansprüche an die Produkte können auf Anfrage bewertet werden.

Hinweise

Langzeitlagerung des Produkts bei einer Durchschnittstemperatur von 50 °C und einer maximalen Luftfeuchtigkeit von 70 %, 36 Monate

ETIM 6.0

EC002643

ETIM 7.0

EC002643

ETIM 8.0

EC002643

ETIM 9.0

EC002643

ECLASS 9.0

27-44-04-01

ECLASS 9.1

27-44-04-01

ECLASS 10.0

27-44-04-01

ECLASS 11.0

27-46-01-01

ECLASS 12.0

27-46-01-01

ECLASS 13.0

27-46-01-01

Zulassungen

ROHS

Konform

UL File Number Search

UL Webseite

Zertifikat-Nr. (cURus)

E60693

Alle anzeigen

farbig

orange

schwarz

silbergrau

Farbe:

schwarz

Best.-Nr.:

8000094097

Art:

MPS APL 5/03 S F2 TN B B D D

Ausfuehrung:

Leiterplattensteckverbinder, Buchsenstecker, Raster in mm (P): 5.00 mm, Polzahl: 3, 180°, Box

Farbe:

orange

Best.-Nr.:

2872550000

Art:

BLZP APL 5.00HC/03/180F SN OR BX

Ausfuehrung:

Leiterplattensteckverbinder, Buchsenstecker, 5.00 mm, Polzahl: 3, 180°, Zugbügelanschluss, Klemmbereich, max. : 4 mm², Box

Farbe:

farbig

Best.-Nr.:

2873480000

Art:

LMF APL 5.00/03/90 3.5SN BX

Ausfuehrung:

Leiterplattenklemme, 5.00 mm, Polzahl: 3, 90°, Lötstiftlänge (l): 3.5 mm, verzinnt, orange, farbig, PUSH IN mit Betätigungselement, Klemmbereich, max. : 2.5 mm², Box

Farbe:

farbig

Best.-Nr.:

2873470000

Art:

LMF APL 5.00/03/180 3.5SN BX

Ausfuehrung:

Leiterplattenklemme, 5.00 mm, Polzahl: 3, 180°, Lötstiftlänge (l): 3.5 mm, verzinnt, orange, farbig, PUSH IN mit Betätigungselement, Klemmbereich, max. : 2.5 mm², Box

Farbe:

orange

Best.-Nr.:

2873500000

Art:

LM APL 5.08/03/90 3.5SN OR BX

Ausfuehrung:

Leiterplattenklemme, 5.08 mm, Polzahl: 3, 90°, Lötstiftlänge (l): 3.5 mm, verzinnt, orange, Zugbügelanschluss, Klemmbereich, max. : 2.5 mm², Box

Farbe:

silbergrau

Best.-Nr.:

2903230000

Art:

SH ETH U

Ausfuehrung:

Schirmbügel, Zubehör, Schraubflansch, Polzahl: 1, verzinkt, silbergrau, Box

This function is provided via the external service provider https://supplyframe.com. By clicking on "Continue" you will be redirected to this page. This leads to a data transfer of personal data to non-European countries. Please check the data protection policy of the external website, for which Weidmüller assumes no responsibility and liability.